Manufacturer supplier exporter of gear rack

GEAR RACK

Manufacturer supplier exporter of gear rack

The guide rail: The groove or ridge made of metal or other material that can bear, fix, guide of moving device or equipment and reduce its friction. Longitudinal grooves or ridges on the surface of the guide rail for guiding and fixing machine parts, special equipment, instruments, etc. The guide rail is also known as slide rails, linear guide rails, and linear slide rails. It is used in linear reciprocating applications and has a higher rated load than linear bearings, and can bear a certain torque at the same time. It can achieve high-precision linear motion under the condition of high load.

gear rack and pinion

Guidance accuracy: mainly refers to the accuracy of the track movement track. The main factors that affect the guiding accuracy are: the geometric accuracy and contact accuracy of the guide rail, the structural form of the guide rail, the stiffness and thermal deformation of the guide rail and its supporting parts, the thickness of the oil film between the static (dynamic) pressure guide rail pair and its stiffness.

gear rack police

(2) Accuracy retention: is mainly determined by the abrasion resistance of the guide rail. The wear resistance is related to the material of the guide rail, the friction properties of the guide pair, the pressure on the guide rail and its distribution, and other factors.

gear rack for sale

(4) Low-speed motion stability: the frictional self-excited vibration is prone to occur when the moving guide rail performs low-speed motion or slight displacement, that is, crawling. Crawling will reduce the positioning accuracy or increase the value of the roughness of the workpiece surface.

Rack and Pinion Gear for Robot

Stiffness: including the guide rail’s own stiffness and contact stiffness. Mainly depends on factors such as the shape and size of the guide rail, the connection method of the supporting parts, and the stress condition.

gear rack pitch

gear rack for drill press

gear rack design

gear rack application

gear rack and pinion cnc

gear rack and rail

gear rack aliexpress

gear rack bunnings

gear rack bushing

gear rack brackets

rack gearbox

rack gear backpack

gear rack cutter

gear rack cnc

gear rack case

gear rack cutting

gear rack for cnc

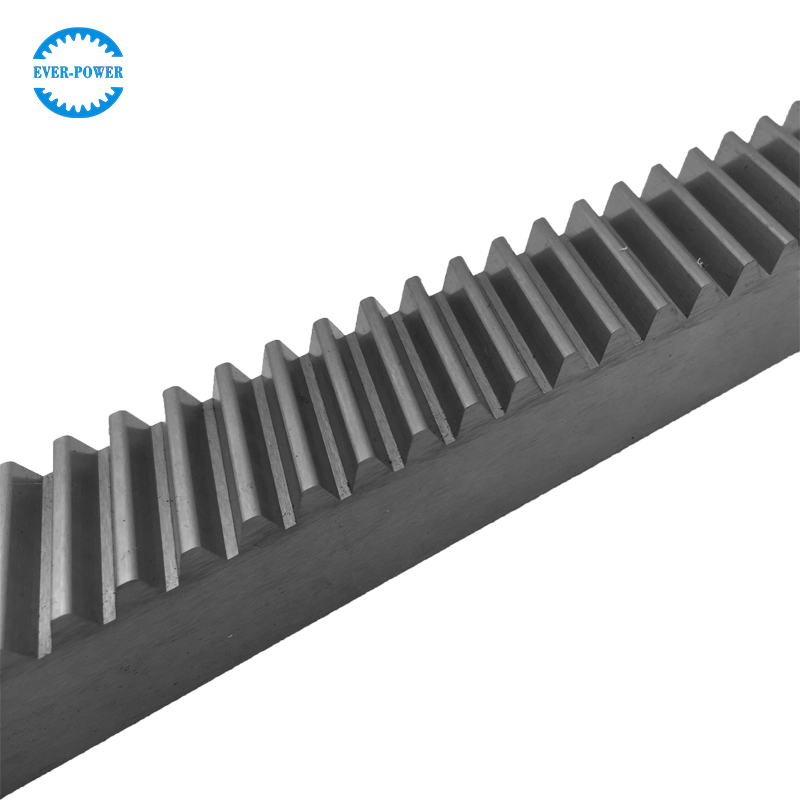

The material selection of the arc or curved gear rack is scientific and reasonable. It fully considers the actual use environment of the project and has good abrasion resistance. Curved gear rack takes full consideration of the specific use environment and the flow characteristics of the material and processes it after selection. It has abrasion resistance and stability after hardening treatment.

Precision design and processing of reliable system: the 70° V-shaped guide surface and cylindrical surface in contact with the rollers, and the stop related to other equipment are finished surfaces. High finish, low noise and linear contact ensure that the guide rail system provides accurate and stable movement.

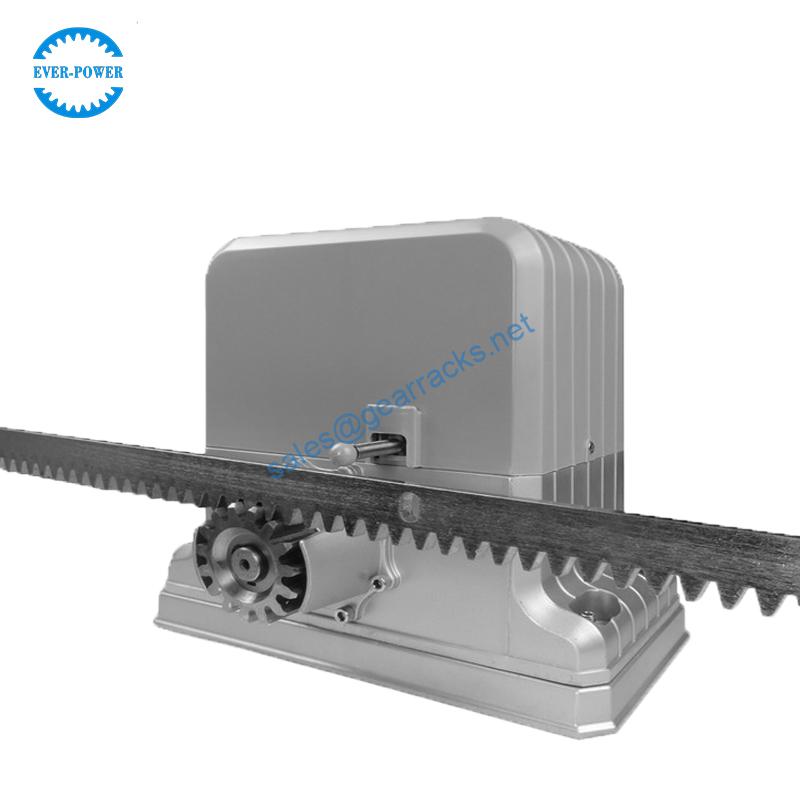

High-precision positioning method and servo drive: according to different working environments, select the scientific and reasonable positioning method. The highest repeatable positioning accuracy can reach 0.03mm. The power system is driven by imported servo motors, it is safe and reliable.

There are many series connection methods: according to different working environments and specific requirements, it is equipped with chain connection methods such as chains, belts, and linkage rods, which is truly scientific and reasonable.

Intelligent control, set the required motion conditions to automatically and intelligently operate, to improve efficiency, and reduce labor and reduce costs.

Simple and convenient maintenance. The arc guide rack uses the automatic lubrication system for easy operation.

Usage / application areas: the circulation lines are widely used in various industries, such as electronic assembly, testing, packaging, laser marking, medical treatment, automotive, welding, semi-automatic assembly lines for automatic machines, etc.

The arc guide rail can be a full circle, or it can be composed of two full 180 degree arc guides, which can be opened and closed. In this way, when the pipe is very long, there is no need to put the arc guide rail from the end and then move it to the required position; or the both ends of the long pipe are limited and there is no place for the arc guide rail to cover up; the arc guide rail can be opened, put it on the pipe, and then close it; see the following application: pipe rotation cutting:

If all you need is arc motion of a certain radian, you can use the arc guide segment; see the following application: rotary spraying:

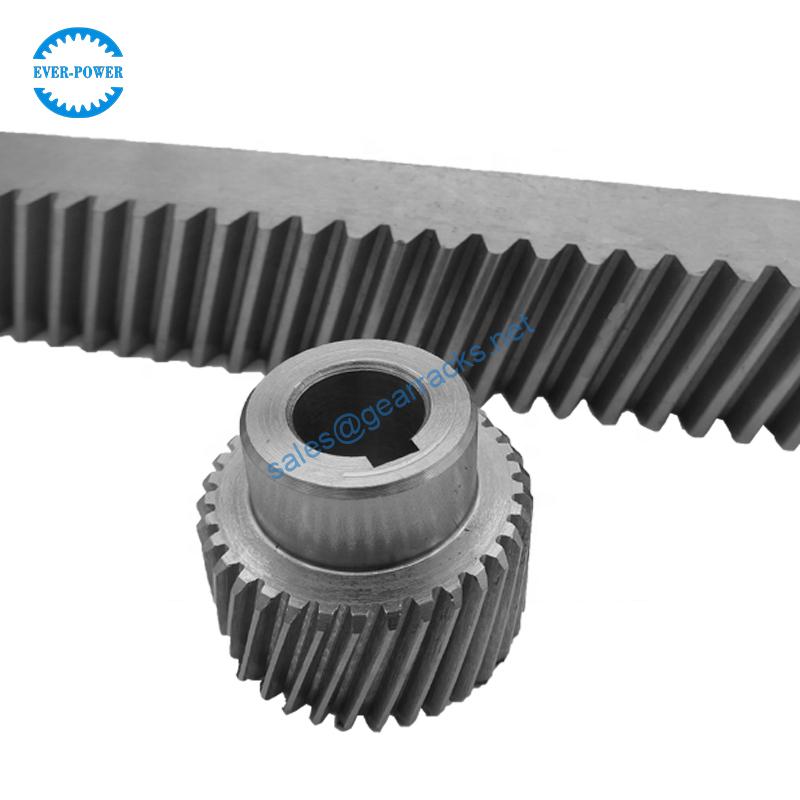

The arc guide rail can be equipped with circular arc rack, the tool is mounted on the slide, and the pinion is driven by the motor to drive the slide to perform circular motion on the circular arc guide, so as to realize the functions of rotary cutting, rotary welding, rotary testing, rotary spraying

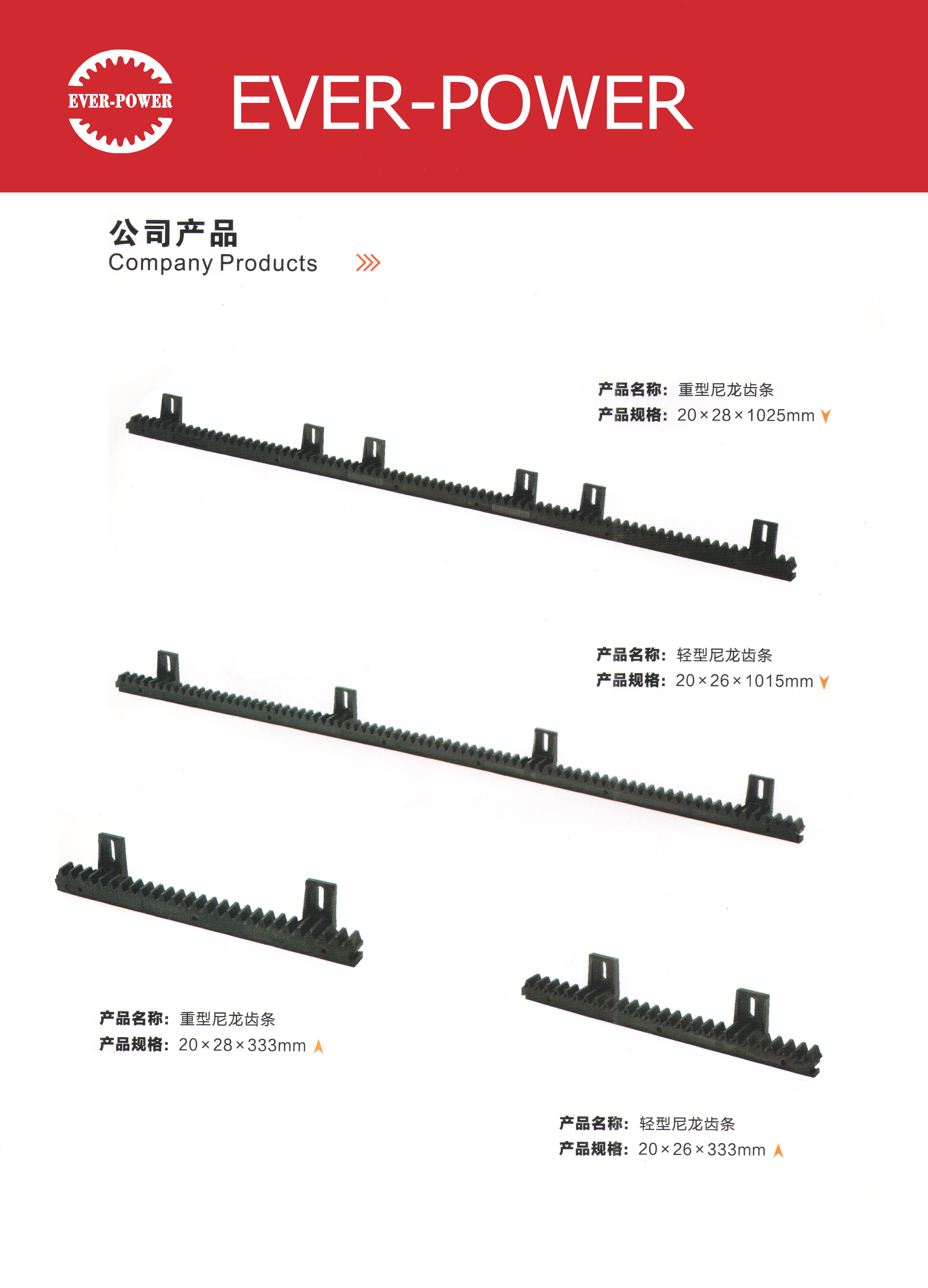

Gear rack

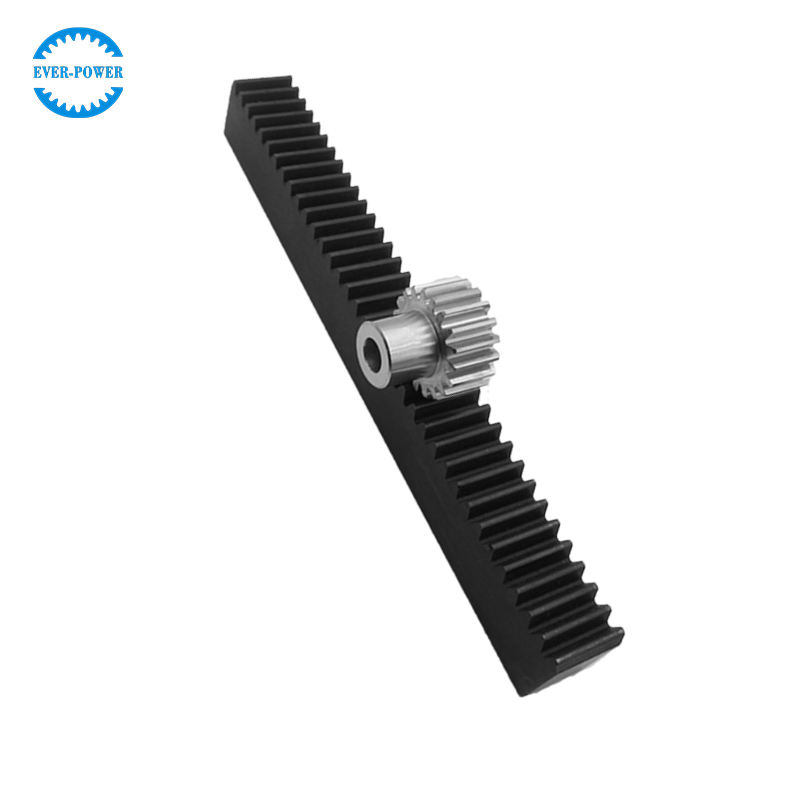

Gear rack and pinion is a type of linear actuator, which comprises a pair of gears that convert rotating motion into linear motion. The rotary motion of a shaft, which is powered by hand or by a motor, is converted into linear motion, when the rack and pinion assembled.

About Us

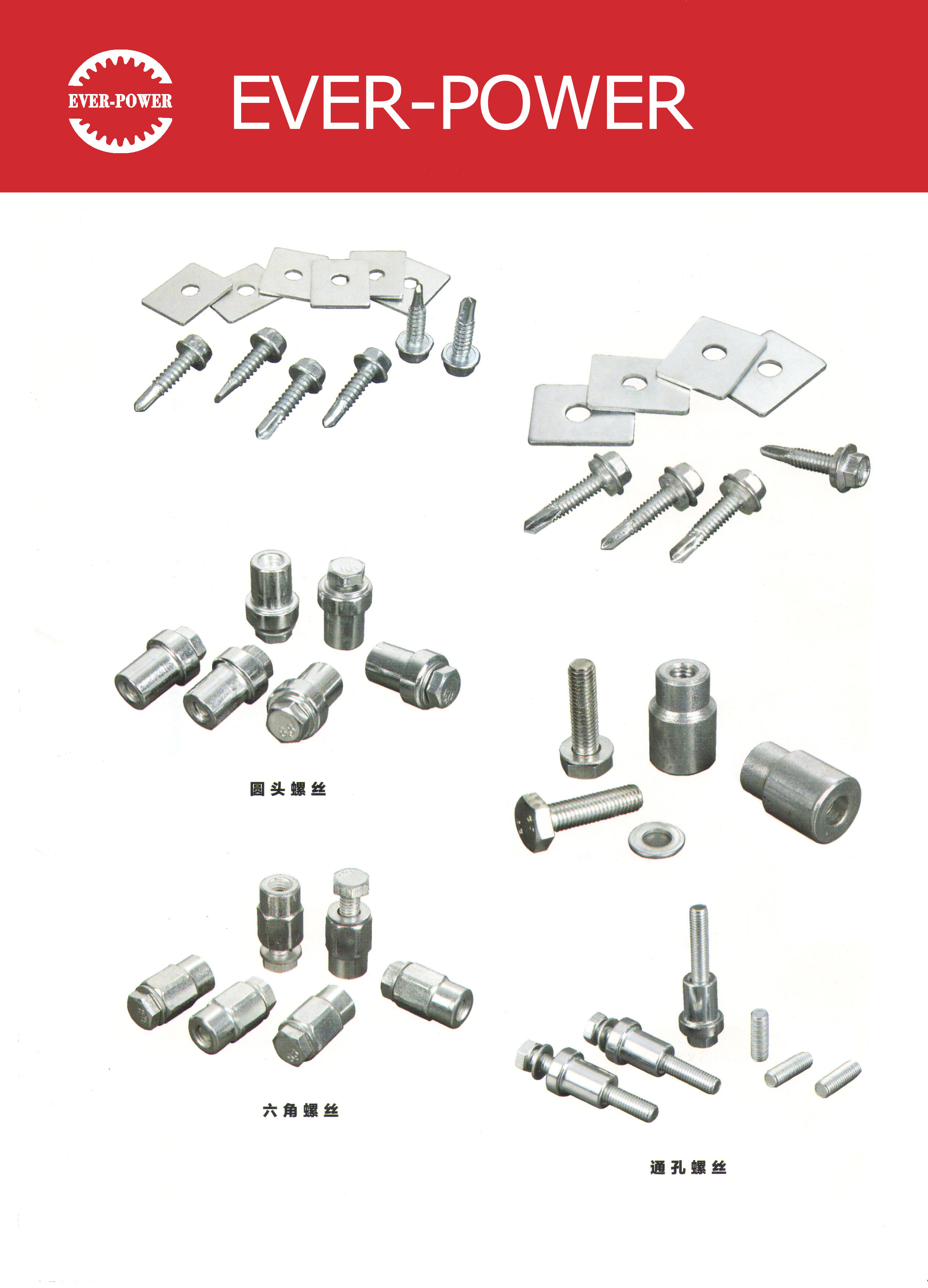

We specializing in the production of Agricultural Gearbox, PTO Shafts, Sprockets, Fluid Coupling, Worm Gear Reducers, Gears and racks, Roller Chains, Sheave and Pulleys, Planetary Gearboxes, Timing Pulleys, Shaft Collars and more.

We have exported our products to clients around the world and earned a good reputation because of our superior product quality and after-sales service.

We warmly welcome customers both at home and abroad to contact us to negotiate business, exchange information and cooperate with us.